Rubber is one of the most versatile materials used across various industries. From automotive parts to electrical safety equipment, it finds applications almost everywhere. But when it comes to its electrical properties, many people have one question in mind: Is rubber a conductor or an insulator? The answer lies in understanding how rubber behaves under different conditions and how rubber’s composition affects its conductivity.

Before diving into rubber’s role, let’s define what an electrical insulator is. An electrical insulator is a material that resists the flow of electric current. Unlike conductors, which have free-flowing electrons, insulators lack these free-moving charges. This makes them ideal for preventing accidental electric shocks and protecting sensitive equipment.

Some of the most common insulators include rubber, glass, plastic, and ceramics. Each of these materials has unique properties that make them effective in preventing electricity from passing through.

To understand the difference between rubber and plastic, click here.

When discussing whether rubber is a conductor, the answer is almost always no. Both natural rubber and synthetic rubber, in their natural states, do not conduct electricity. They act as barriers to electrical flow because of their tightly bound molecules. These molecules prevent electrons from moving freely, which is essential for a material to conduct electricity.

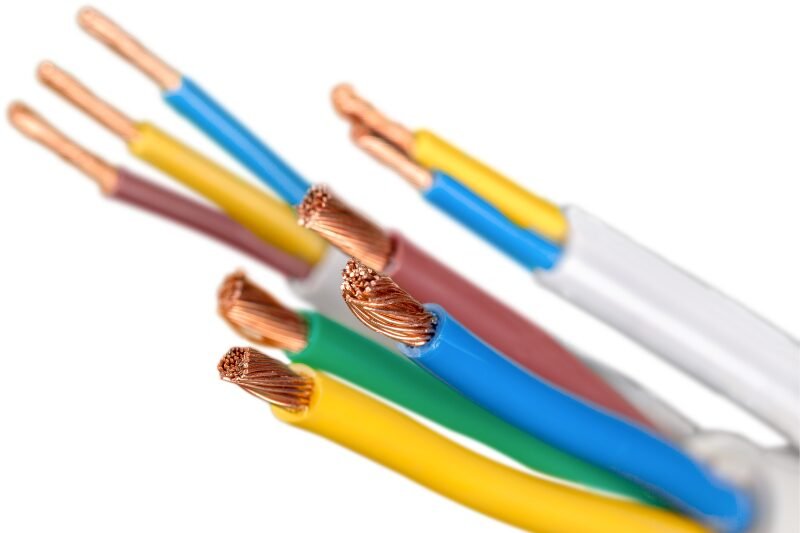

However, there are exceptions. Conductive rubber can be created by adding specific conductive fillers, such as carbon black or metal powders. This allows rubber to have specialized applications where a balance between flexibility and conductivity is needed, like in EMI/RFI shielding and electronic gaskets. This is why electricians often wear rubber gloves when working with electric wires. Rubber provides an extra layer of protection by acting as an insulator.

However, it’s essential to note that rubber is not a guaranteed safeguard against electrical shocks, especially in the presence of high voltage. If a powerful enough voltage is present, it can cause even insulating materials like rubber to conduct electricity. Moreover, if rubber becomes wet, its insulating properties can diminish, posing a risk to those relying on it for protection.

The conductivity of rubber is a fascinating topic because it depends largely on its composition and modifications. Pure rubber is inherently an insulator due to its molecular structure. In other words, the atoms within rubber are arranged in a way that prevents the free flow of electrons.

Why is Rubber Not Naturally Conductive?

In its natural state, rubber’s electrons are tightly held within covalent bonds, creating a barrier that restricts the flow of electricity. This results in a high resistance level, often ranging between 10^13 and 10^15 ohms per square centimeter. However, when rubber is mixed with conductive additives like carbon black, its structure changes, allowing electrons to move and making it slightly conductive.

Rubber engineered with these conductive additives falls under the umbrella of Conductive Rubber, a term used to describe rubberized materials that possess properties to reduce or eliminate EMI/RFI (electromagnetic interference and radio frequency interference). This type of rubber is essential in electronics to shield against disruptive electrical noise.

The short answer is yes. Rubber’s status as an insulator is well-established due to its high resistance to electrical flow. In metals, electrons in the outer shell aren’t tightly bound to any specific atom, which allows them to move freely from one atom to another. When a voltage is applied, it pushes these free electrons, creating a current flow.

Rubber behaves differently. Unlike metals, the electrons in rubber are strongly attracted to their atoms and don’t move freely. This means that when a voltage is applied, the electrons in rubber remain “loyal” to their specific atoms, resisting the push to move. As a result, it acts as a barrier to electrical flow, making it an ideal insulator.

However, that doesn’t mean rubber is invincible. If a high enough voltage is applied, rubber can reach what’s called its ‘breakdown voltage’. At this point, the rubber can no longer hold its electrons in place, causing the material to heat up dramatically. This heating can lead to an electrical arc, where the rubber’s resistance collapses, creating a plasma channel through which the current flows. While this scenario is rare in typical applications, it’s a reminder of why rubber is chosen for its insulating properties and where its limits lie.

Rubber’s versatility as an insulator allows it to be used in a wide range of applications, from household products to industrial safety gear. Here are a few of the most common uses:

For a deeper dive into the environmental impact of rubber-based products like rubber bands, take a look at the blog discussing the environmental impact of rubber bands.

While rubber is mainly known as an insulator, it can be engineered to become conductive. Conductive rubber is a type of rubber that includes additives like carbon or metal fillers. These fillers create pathways for electrons to move, increasing the material’s conductivity.

Conductive rubber is primarily used in applications where electromagnetic interference needs to be controlled, such as in EMI/RFI shielding gaskets, specialized cables, and connectors. This unique material provides a balance between flexibility and conductivity, making it ideal for electronic applications.

In addition to being an electrical insulator, rubber is also an effective insulator of heat. This property is due to rubber’s low thermal conductivity, which ranges from 0.09 W/m.K to 2.5 W/m.K at room temperature. In the process of heat conduction, molecules at a higher temperature seek to pass their energy to lower-temperature molecules. However, rubber’s molecular structure prevents this energy transfer, making it a reliable heat insulator.

This dual insulating nature of rubber makes it an ideal material for use in insulating blankets, handle grips, and thermal insulation sheets in both industrial and household applications.

At Min Yuen, we deliver tailored rubber solutions for medical, exercise therapy, and industrial sectors, focusing on quality and innovation. Our range includes Natural Rubber, Latex-Free Synthetic Rubber, NBR Nitrile, and CR Neoprene—each engineered for optimal performance and durability in diverse applications. From healthcare to industrial manufacturing, Min Yuen’s rubber products offer reliability and precision, crafted to meet the specific demands of your business.